When voltage is applied to any given piezoelectric-based component in the printer, the piece quickly flexes, sends a shockwave through the nozzles, efficiently pushing ink out the tips. For instance, in the newest class of inkjet printers, extremely small nozzles with a piezoelectric bimorph at the base are used to deploy ink more precisely than ever before. Piezoelectric bimorphs products are often integrated into applications in the form of disc actuators, commonly seen in valve, pump, and fan control applications, especially those on a microscopic scale. The right piezoelectric company partner can manufacture fast-turn piezoelectric product samples for a wide range of sound production products requiring extremely low power, in smartphones, miniature alarms, sophisticated micro-buzzers, electric cars and many other sound producing devices.

While a single piezoelectric crystal can only shrink or expand by a few millimeters at most, bimorphs can bend well over ten or a hundred times that range at the same voltage.

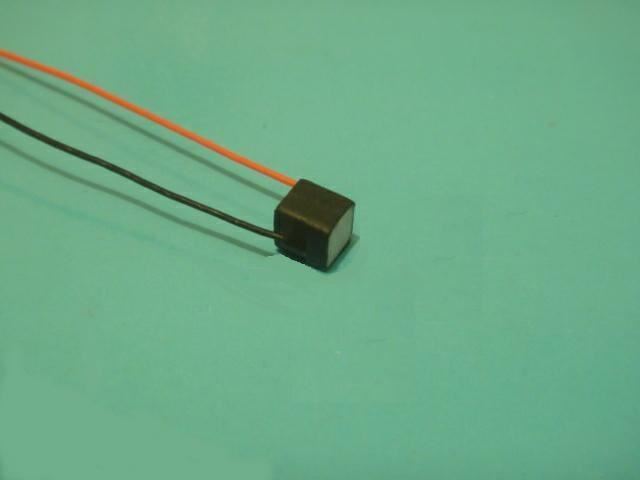

This is a way to greatly magnify the power and range of a piezoelectric actuator, while using very little electrical current. Piezoelectric bimorphs involve two separate pieces of piezoelectric ceramic put together in such a way that when a voltage is applied, the piece bends. Piezoelectric component manufacturers are now enabling ‘short-runs’ of unique, one-of-a-kind piezoelectric bimorphs, as well as piezoelectric transducers and other classes of piezoelectric products, greatly expanding the total available market. In the past, piezoelectric manufacturers needed to charge substantial upfront development fees, forcing companies to find other older, less power efficient solutions, instead of enjoying the incredibly cost-effective and low-power advantages of piezoelectric-based products and multi-layer piezoelectric actuators. These specialized piezoelectric companies can now deliver testable piezo-based production samples in a matter of weeks. Rising to this need to reduce the cost of state-of-the-art piezoelectric products, a new class of piezoelectric companies have now developed innovative production techniques to cost-effectively provide fast-to-market, low-production-run samples of multilayer piezo actuators. Piezoelectric products are indeed very complex and can be quite difficult to design and manufacture. Piezoelectric manufactures are now able to provide piezoelectric product solutions to companies that in the past could not afford the steep, upfront design fees, especially for their new products that sometimes take years to ramp up to sufficient production levels. A new class of miniature, highly-specialized instruments, alarms and sound production devices, requiring very low power consumption, are needed in countless emerging applications. In the last decade, piezoelectric bimorph applications worldwide have expanded dramatically.

0 kommentar(er)

0 kommentar(er)